Control over energy consumption and impacting indicators in regular intervals to determine energy efficiency, and normalization of the level of energy consumption by avoiding cost overconsumption of energy resources

allows you to set overconsumption of fuel and energy resources per day or shift.

allows to identify wasteful energy consumption and their reasons.

reveals teams, which allowed overconsumption of energy resources and teams, which provided fuel and energy savings.

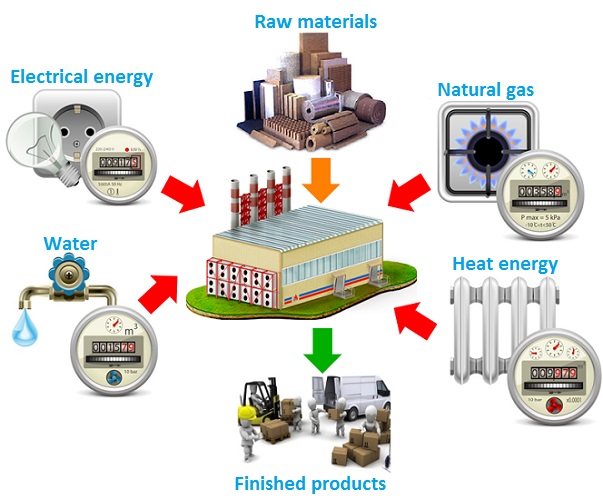

metering devices readings on all types of fuel and energy resources used in the facility

production volume, quality of raw materials and others.

Data collection and data entry may be performed both by using automated systems and manually.

Database on the following indicators is created based on the information entered (daily):

energy consumption

thermal energy consumption

natural gas consumption

coal consumption

cold water consumption

hot water consumption

compressed air consumption

steam consumption

tariffs for energy resources

output volume

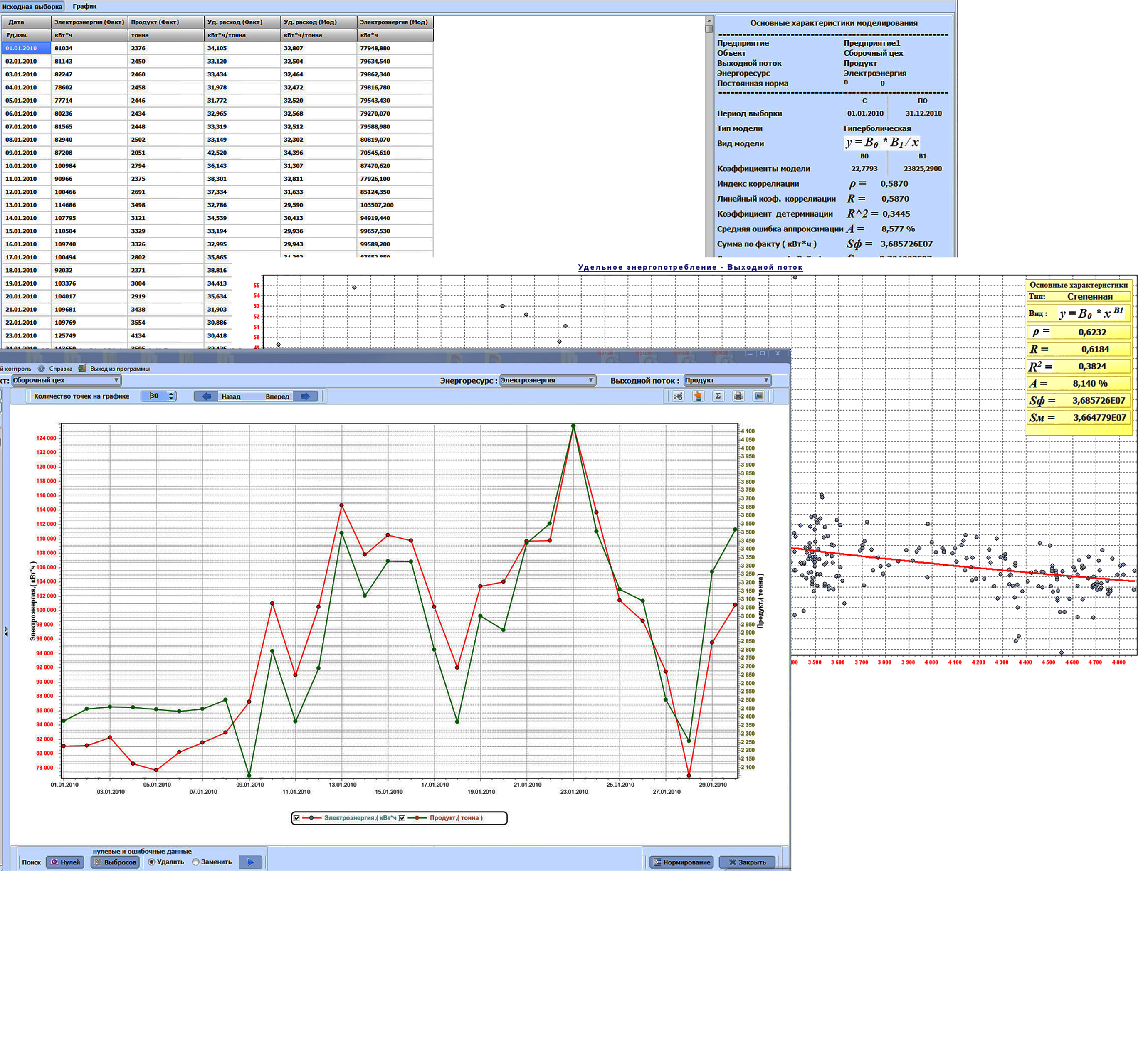

Data analysis and calculation of specific consumption rates of energy per unit of output are performed on the basis of the received information. But, taking into account that in market conditions volume of production is constantly adjusted in line with demand, it is correct to use not constant, but dynamic specific rate, which varies in time and depends on the volume of output, quality of raw materials and others.

On the web-platform dynamic rates are described through mathematical models of linear, exponential, hyperbolic, and logarithmic types.

Control of the current energy consumption with the aim of not exceeding the targets set in the previous step is carried out at this stage.

In case of exceeding the current values for more than 5-10 %, steps to identify the causes and further prevention should be taken.

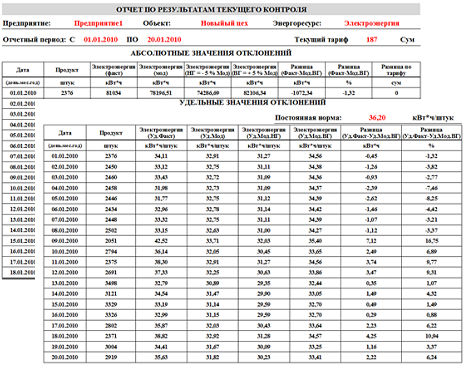

Reports, reflecting the following indicators are generated according to the results of current monitoring of energy consumption:

specific data on energy consumption;

data on absolute values of deviations;

cost overrun based on the current tariff.

Reports are converted into PDF-files.

Energy management tools for effective energy utilization via eliminating losses in real time, and stimulating further work on energy saving

Objective criteria of energy saving in market conditions.

Different types of energy consumption control: operational, in-depth, team.

Reducing energy intensity of production and a share of energy consumption in production costs.

Scalable software product, monitoring objects of which may be power plants, production lines, shops and businesses.

Useful tool in carrying out energy audits.

Lowering the declared capacity and elimination of fines for it exceeding

Possibility to identify wasteful energy consumption and main reasons for their occurrence.

Mechanism of motivation of employees, leading to reduction in consumption of energy resources.

Possibility to perform control on Deming cycle, which is the basis of ISO 50001 energy management international standard.

Scientifically proven planning of consumption of fuel and energy resources.