System analysis of energy consumption of industrial enterprises

Conducting express energy audit of companies

Investment audit of a company

Development of energy efficiency project

Search of investments, development of financial mechanism for implementation of the energy efficiency project

Implementation of the energy efficiency project and monitoring its implementation

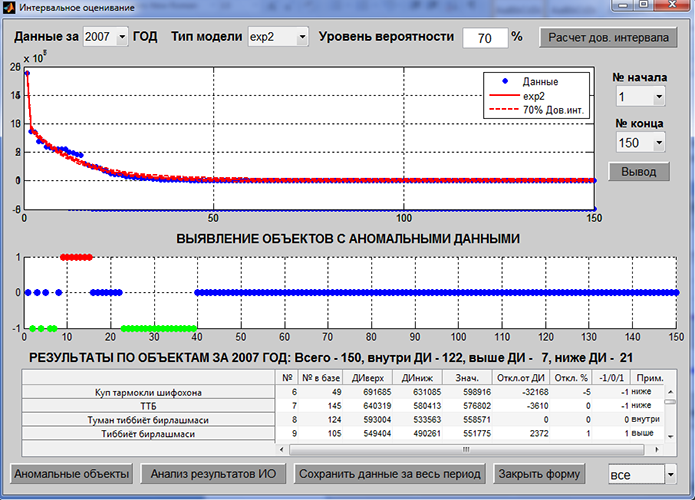

Interval estimation – is a procedure of determining the enterprises, energy consumption of which exceeds permitted range made on the basis of ranked data on energy consumption of the enterprises. Enterprises for express energy audit are defined according to the results of assessment.

Express energy audit of enterprises makes it possible to determine actual energy consumption, identify causes of irrational use of energy resources and energy saving potential of the company, develop a list of key energy-saving measures and identify priority directions for reducing expenditures for energy products.

Investment energy audit analyzes technical aspects of energy efficiency more deeply, as well as considers possibility of investing in energy saving projects. When conducting investment energy audit it is necessary to analyze a number of key factors: degree of complexity of equipment, ability of operational and maintenance staff to operate the equipment effectively; condition of electromechanical equipment; budget for repairs and replacement of equipment, and many others. After completing analysis of factors within the investment energy audit it is necessary to evaluate risk of each of these factors and corresponding costs. All these risks should be taken into account in financial structure of any energy project (especially for projects with guaranteed savings).

Installation of reactive power compensation devices (RPCD)

Replacement of outdated models of transformers to current models

Use of frequency control system in motor drives on objects with variable load (ventilation systems, pump stations, etc.)

Installation of energy consumption monitoring systems

Replacing existing lighting system to more energy-efficient system

Painting rooms in bright colors, reducing use of personal appliances, etc.

The key to successful completion of the project is continuous monitoring and control of the energy efficiency project execution.

Monitoring and control assumes: evaluation of efficiency of the measures implemented on the basis of the actual data, i.e., data analysis and evaluation of reducing in consumption in comparable conditions (conditions, in which activity that affects volume of consumption of energy resources, is carried out, which are similar to the conditions of its activities in the period in which the base of the volume of consumption is determined)

Economic effect in the form of reduced energy consumption per unit of production and increased competitiveness of the products in the market

Monitoring of implementation of the projects assures timely and quality execution of works.

Modernization of the equipment reduces risk of accidents, equipment failure.

Identification of companies with abnormal energy consumption for further energy examinations.

Investment energy audit allows determine financially effective projects that reduce running costs